Re-hardening filter and mineralizer maintenance

The re-hardening water filter JOWA F-75 maintanance

The re-hardening water filter JOWA F-75 should be back-flushed regularly. The frequency will depend on the extent of water contamination and varies form once a week to twice a week. The adjusting media is used up in proportion to the alkalinity of water and should be refilled in proportion to the consumption. It is therefore necessary to check the pH-value regularly. New filter material should be filled through the upper manhole.

During flushing the handles should be turned to an upward position and the water direction in the filter is changed (second figure below). Flushing should proceed for about 10 minutes or until relatively clear water comes out through the flushing outlet. After flushing, the handles should be re-set back to normal working position (first figure below).

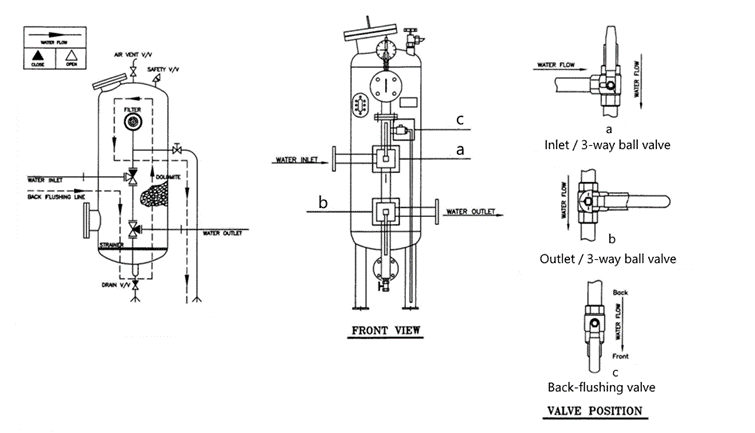

Flow diagram of the Re-hardening Water Filter JOWA F-75

a – normal working flow, b – back flush flow

Re-hardening water filter HANSUN FIL-1.5 maintenance

The re-hardening water filter should be carried out periodic maintenance, so that the unit is kept in regular condition. When the filter tank running for long time, there is some dirties stained and solids contained inside of vessel, this will cause high pressure drop, and reduce filtering and re-hardening capacity. Thus, the unit is intended to be back-washing regularly, meanwhile the filter material to be replaced annually.

Back-washing the filter tank

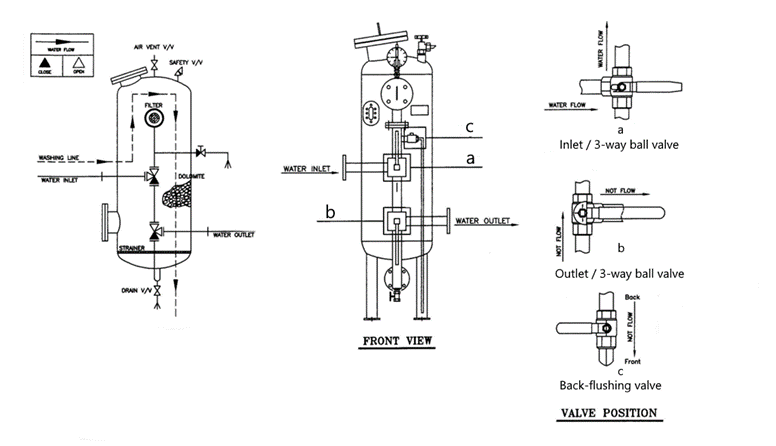

1. Turn both handles upward (second figure below)

2. Keep unit back-washing time for more than 2 minute

3. Turn both handles downward, and turn to normal status (first figure below)

Fore-washing the filter tank

The tank is also need fore-washing regularly

1. Turn both handles downward

2. Turn on drain valve slowly

3. Flushing out settlements via drain valve

4. Close drain valve

5. Unit running in normal order

Cleaning and replacing of filter material

The filter material is to be replaced periodically we recommend filter sand and PH media to be replaced annually, so that the unit can be running in good order.

Normally the filter sand

in the lower part to be filled 100…200 mm above on the lower-distribution, then

PH media in the upper part to be filled 100…200 mm under the upper-distribution

(second figure below).

Filter flow diagram: a – normal working flow (both handle down), b – back wash flow (both handle up)

Follow up to change filter material

1. Shut off inlet and outlet valves

2. Open the drain valve, drain the tank completely

3. Open top handhole cover, then open low handhole cover

4. Take out filter material from low cover

5. Make sure no damage to distributor

6. Washing tank inside with freshwater, and clean and drain completely

7. Close low handhole cover and tighten it

8. Fill with filter material carefully

9. Close top handhole cover and tighten it

10. Slowly open inlet valve, check no leakage

11. Open outlet valve keep unit in normal operation

DONG KWANG DKM-10 mineralizer maintenance

Maintenance of the mineralizer very similar to re-hardening filters and conclude next main procedures:

- back-flushing must be done every week, otherwise pressure drop will be rise.

- recharging the dolomite and re-hardening material must done per 2 years, but when PH valve is lower than 6.0, recharging activity must be done.

- when recharging the dolomite and recharging material, clean the strainer.

DAE HEUNG Mineralizer maintenance

The mineralizer should be carried out periodic maintenances. Thus, the unit is intended to be back-washing regularly, meanwhile the mineralizer dolomite media to be cleaned every 2 month and replaced annually.

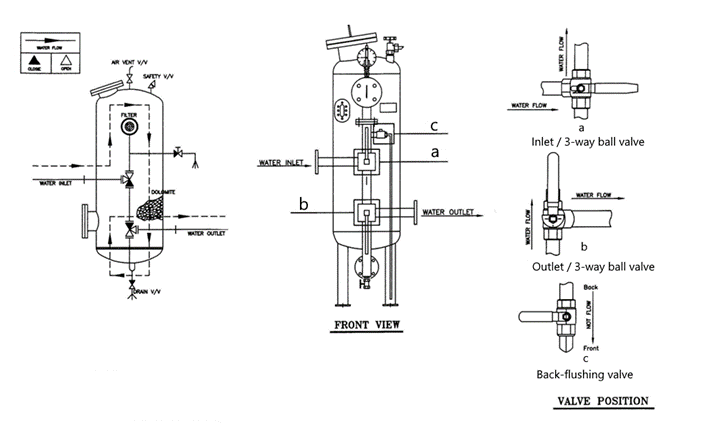

The main maintenance procedures are back-flushing (first figure below) and washing (second figure below). In the figures shown valve positions according to maintenance procedure.

Mineralizer back-flushing

Mineralizer washing

Mineralizer valves positions for normal working condition shown in the figure below.

Mineralizer normal working