Sterilization

The water, which is generated for drinking purpose by FWG on board of vessel or supplied water in port, has plenty of germs and bacteria, therefore this water should be disinfected before drinking by the appropriate method.

Generally, uses below methods:

- chloritization

- O3 sterilization

Among those sterilization methods, UV sterilization is widely used. Because it is easy to control, maintenance and repair with simple structure.

The sterilizer is composed of UV chamber, filter housing, control panel. UV chamber has body, quartz sleeve (water tube), UV lamp and so on. Filter housing has body, filter elements and control panel has all electric items for operating.

It is well known about sterilization action in the ultraviolet rays like in the wind or sterilization by sunning so long. The sterilization system of ultraviolet rays is not approved perfectly, but it is considered that the ultraviolet rays may be break down it. It is affected by the ultraviolet ray which effect changes of nucleic acid (DNA) and lost multiplication capacity due to metabolic obstacles.

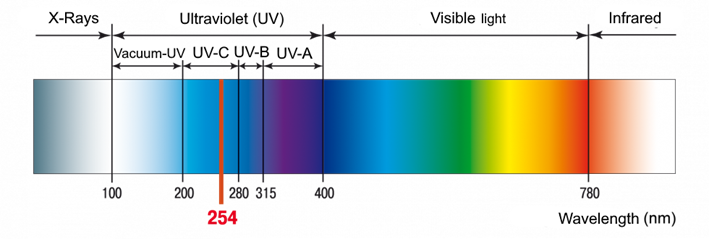

Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light (400 nm), but longer than X-rays (100 nm) (see figure below).

The classification of the wavelength range at the ultraviolet rays

UV-A: 315…400 nm

UV-B: 280…315 nm

UV-C: 200…280 nm

Ultraviolet radiation covers the wavelength range from 100 to 400 nanometres. The disinfection process uses wavelengths in the UV-C range from 200 to 280 nanometres, while the oxidation process uses the wavelengths down into the Vacuum-UV range below 200 nanometres.

The electromagnetic spectrum (UV and Visible light)

Ultraviolet sterilization technology uses UV light to target and disable disease causing microorganisms (pathogens, viruses, colitis germs and bacteria). The UV light used, resided in the UV-C range of the light spectrum. Specifically, they discovered that light in the 254 nanometre (nm) range was the most effective (excellent germicidal effect).

The 4 actions of the Ultraviolet rays

1) Photochemical reaction (Actinic rays: 356 nm): synthetic chemistry, fluorescence action.

2) Stigmatism reaction (Health rays: 297 nm): stigmatism reaction.

3) Sterilizing action (Sterilizing rays: 254 nm): every kind sterilizing

4) Ozone development: sterilization, deodorizing action

The structure of UV lamp

Generally, intensity of ultraviolet ray could be so various depending on the type and pressure of gas that proper design must be performed to satisfy the range of ray for the intended purpose as considering to characteristic of each industry.

Glass tube should be made of special material or quartz for efficient permeability. Tungsten filaments are installed on both side and calcium oxide, barium oxide, etc is applied on surface of lamp for efficient radiation of electron.

Some mercury, argon gas or other inert gas mixed inside of lamp.

If the current flow into both pole and electrons

start to radiate, electric discharge between mercury and argon gas start to

occur by peening effect (see figure below). After the electrons crashed metallic atom, resonant

line appears on process of succession. As UV ray lamp uses resonant line of

ultraviolet ray, it efficiently radiates ultraviolet ray through special glass

or quartz which has excellent permeability.

Illustration of UV lamp working principle

To the main particulars of UV sterilizer commonly belongs: capacity (m3/h), number of lamps, working pressure (MPa), design pressure (MPa), hydraulic test pressure (MPa), dimensions chamber (d×h mm), dimensions control unit (l×b×h mm), total pressure drop (MPa), UV dosage (μWs/cm2), UV lamp power consumption (W) and change period.

Flow diagram of UV sterilizer DKU-10 shown in the next figure.

Flow diagram of UV sterilizer DONG KWANG HI-TECH CORPORATION DKU-10

General view of UV sterilizer JOVA UV1 shown in figure below. The UV sterilizer is meant to sterilise the potable water before it reaches the tapping point. It contains highest quality ultraviolet lamps which are powered by electronic, high-frequency, ballast to reach the best light quality and longest lifetime for the lamps. The length of life is 8000 hours. It is important to change lamps after this time to avoid unnecessary breakdowns. The wavelength is 254 nm.

General view of UV sterilizer JOWA UV1

1 – UV lamp chamber, 2 – mounting frame, 3 – control cabinet, 4 – solenoid valve, 5 – drain valve

The HANSUN UV Sterilizer UIV-1.3 unit is designed to provide disinfection to potable water onboard same as presented UV sterilizers above. The whole system includes stainless steel UV vessel, UV sensor, UV-lamp, Quartz tube, solenoid valve and control cabinet

The HANSUN UV Sterilizer UIV-1.3 general view

1 – drain valve, 2 – vent valve, 3 – pressure gauge, 4 – gauge valve, 5 – flow control valve, 6 – strainer, 7 – water inlet flange, 8 – solenoid valve, 9 – pressure gauge, 10 – water outlet flange, 11 – frame, 12 – vibration absorber, 13 – UV vessel, 14 – control cabinet

The control cabinet is equipped with CPU board, which arranged on cabinet cover, there is power and alarm LED arranged on front of cover.

The controller contains necessary information that displays in different manual bar, which includes UV intensity, hour meter, trouble shorting, alarm list and contact information. There is arrow key available for page turning.

Once alarm rising, certain information to be displayed on screen of controller.

UV lamp and its connection

1 – cable gland, 2 – female socket, 3 – UV lamp socket, 4 – UV lamp

The UV-lamp gives 8000 hours life, the UV ray reaches 254 nm that specially designed for potable water sterilizing.