Vacuum FWG plant with plate type heat exchangers

Nowadays vacuum FWG plants with plate type of heat

exchangers (condenser and evaporator) broadly uses on board of different

vessels. They are many manufacturers provide it such as Alfa Laval, Sondex,

Wartsila, Gea etc. Meanwhile they have similar working principal and general

design. Below provides description of working principle and general design some

of them.

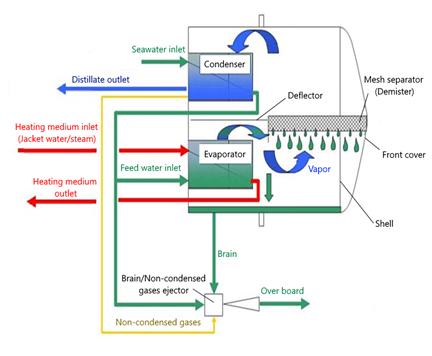

The vacuum FWG plants with plate type of heat exchangers utilizes the heat from diesel engine jacket cooling water to produce distil water by evaporating seawater under high vacuum enabling the feed water to evaporate at temperatures about 35-60 °C as it passes between the plates heated by the heating medium. Steam can also be used as heat source instead of high temperature jacket cooling water.

Generally, the FWG plant consist of 2 sets of plate type heat exchangers acting as an evaporator and a condenser respectively, and also combined brine/non-condensed gases ejector, SW ejector pump, distil water pump, salinometer and control panel (see figure below).

1 – front cover, 2 – generator shell, 3 – condenser, 4 – evaporator, 5 – combine brine/non-condensed gases ejector, 6 – distil pump, 7 – bed frame, 8 – salinometer, 9 – control panel, 10 – heating medium (engine jacket cooling water) inlet valve, 11 – heating medium (engine jacket cooling water) outlet valve, 12 – by-pass valve

The SW ejector pump provides a continuous supply of sea water to the FWG plant. This sea water supply acts to cool the vapour in order to condense it. It serves as a feed supply to the evaporator and for the brine/non-condensed gases ejector.

The evaporation chamber is kept under vacuum of 85-95 % by the brine/non-condensed gases ejector driven by the seawater outlet from the condenser (see figure below). The feed water evaporates when entering the evaporator due to the vacuum condition. Water spray and droplets are partly removed from the vapour by the deflector mounted on top of the evaporator and partly by a build-in mesh separator (demister). The separated seawater droplets fall due to gravity into the brine sump, which is extracted from the shell by means of the brine/non-condensed gases ejector.

The clean distil water vapors passing through demister continue to the condenser, where they condensed into pure distillate as they pass between the cold plates cooled by incoming seawater. The distilled water will be taken out by means of an integral distil water pump to the water storage tanks. The quality of distillate taken out from the condenser will be controlled by a Salinometer to supervise that the pre-set salinity will be reached. If the salinity exceeds the specified level, the solenoid valve in the discharge line of the FWG pump is automatically activated and faulty distillate is returned to the feed line or dumped into the drain. The Salinometer can be connected to remote alarm so that a too high salinity is registered immediately in the control room.

Working principle of the vacuum FWG plant with plate type of heat exchangers

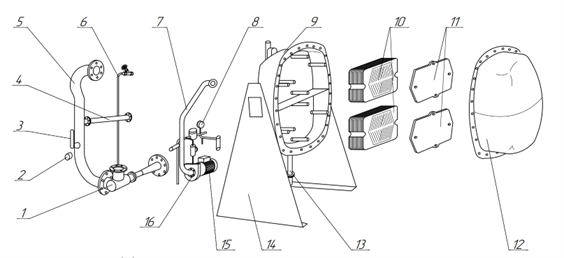

Main parts of plate type FWG Alfa Laval JWP-26-C main parts shown in the figure below.

Plate type FWG Alfa Laval JWP-26-C main parts

1 – combine brine/non-condensed gases ejector, 2 – non return valve, 3 – thermometer, 4 – feed water pipe, 5 – seawater pipe from condenser, 6 – vacuum pipe, 7 – freshwater pipe to pump, 8 – pressure gauge, 9 – generator shell, 10 – heat exchangers (condenser and evaporator correspondingly), 11 – pressure plates, 12 – front cover, 13 – brine pipe, 14 – bed frame, 15 – freshwater pump motor, 16 – centrifugal freshwater pump