Domestic and potable water system general information

Domestic and potable water systems belong to general ship systems group. Also, this group include engine room water services system. These systems must be designed according to national sanitary requirements and classification societies regulations.

The main purpose of the domestic and potable systems it is an ensure proper crew and passengers habitation condition on shipboard such as physiology, sanitary, hygiene needs and domestic demands by potable, fresh and sea water providing.

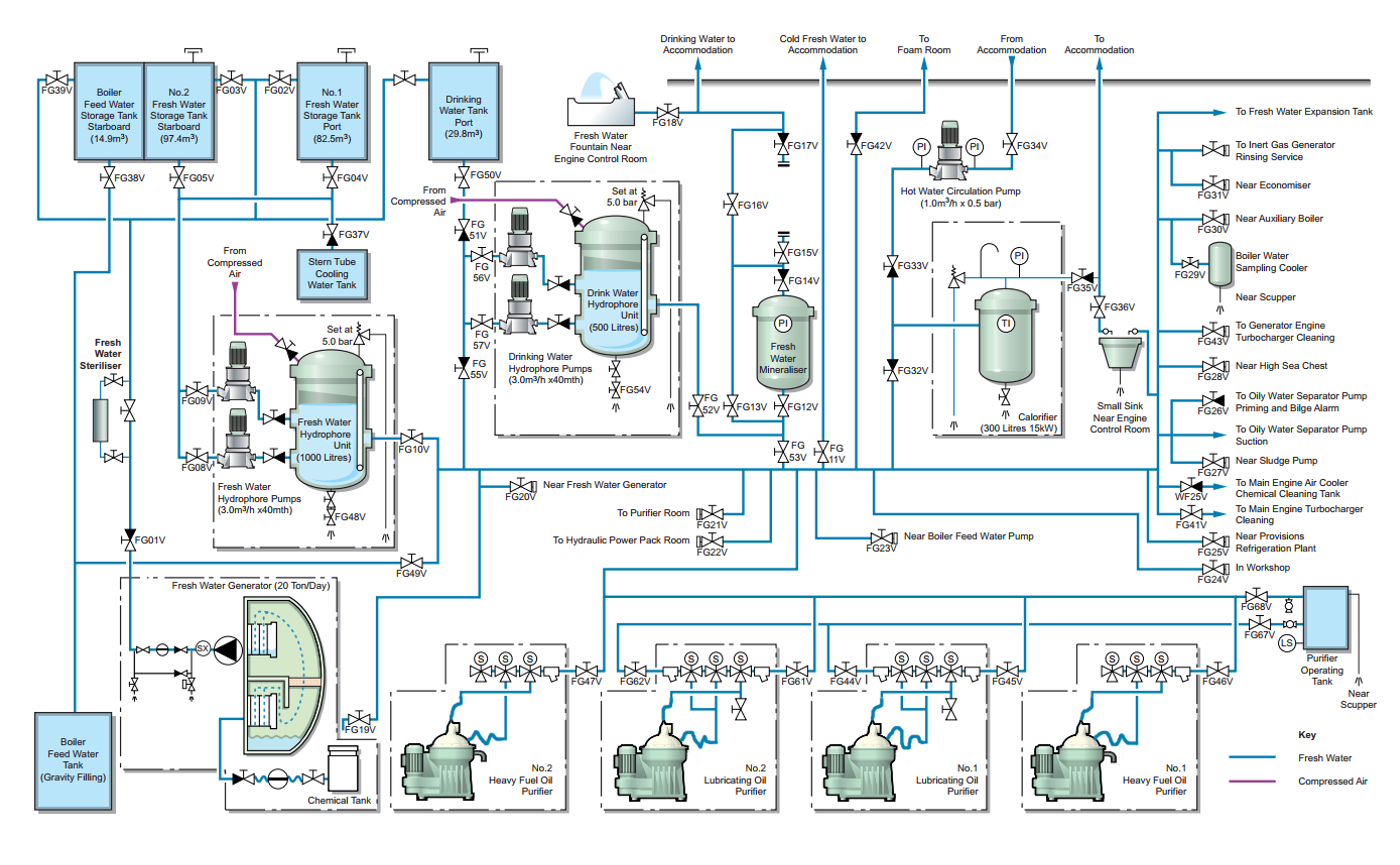

Fresh water or distilled water for domestic and engine room use is stored in two storage tanks at least for marine vessels. For river and cabotage vessels possible one tank. Quantity and capacity of tanks depend on vessel type and water consumption. Water tanks inside has a special protective covering it can be paint, epoxy resin etc. Potable water as a rule is stored in separate tank. The names and sign of tanks on shipboard can be different for instance, PT TK or DRNK TK, FW TK, DIST TK etc.

Fresh and potable water can be taken from a shore supply when in port or a barge when at anchorage by means of water bunkering lines which manifolds located on both (port and starboard) sides of the vessel. On board water tanks are normally filled with water from the FWG. The distilled water produced by the FWG is discharged to the storage water tanks (FW TK, DRNK TK or DIST TK). Distillate which is to be pumped to the domestic water tanks can be passed through a re-hardening filter and/or a silver-ion steriliser. Water supplied from ashore or a barge does not pass through the silver-ion steriliser and care must be taken to ensure that the water is fit for human consumption. The silver-ion steriliser destroys bacteria and leaves a residue of silver ions in the stored water thus providing for effective sterilisation whilst the water is stored in the tanks.

As the water passes between two electrodes in the sterilizing unit, through which a small current is passed, the ions are released and sterilize the water. Sterilization by this method ensures that the water is maintained in a good condition, even when stored in the tanks for a period of time. The silver electrodes should be inspected and changed when all the silver coating has depleted. The dosing of the water is automatic and is set depending on the flow of the water.

Normally one storage water tank is in use, with the second being filled or ready for use.

Water is supplied to the domestic and service FW systems from the storage water tank in use by one of the two (duty/standby) pumps, which discharge to the hydrophore tank. The duty pump operates automatically, starting and stopping according to the pressure in the hydrophore tank. As the water is used, the tank pressure drops allowing duty pump to start and refill the tank. As the pressure in the system increases to a predetermined value the pump will automatically stop. The hydrophore tank has a capacity around 1.0 m3 and is supplied with compressed air in order to maintain the tank under pressure. The drinking water tank supplies a similar but separate hydrophore tank and water treatment can be made by an ultraviolet sterilizer, and a mineraliser.

The duty and standby pumps can be changed over if necessary for maintenance. Also pumps should be changed over periodically in order to avoid one pump having excessive running hours.

Typically, the FW hydrophore tank supplies the water into:

- Accommodation service cold water

- Accommodation (domestic) hot water system

- Engine room system and services, such as: sewage treatment system, FO and LO purifiers operating water system, FW cooling system (expansion tanks), bilge oil/water separator system, ME turbocharger cleaning, chemical dosing units, auxiliary engine turbocharger cleaning, FWG chemical tank filling, inert gas system, ME chemical cleaning tank, ME air cooler cleaning, oil discharge monitoring equipment, boilers sampling coolers, hotwell/cascade tank, etc. Also, in different places of ER located freshwater valves for a water supply (see figure below): near freshwater generator, near economiser, near sea chest, near auxiliary boiler, in workshop, etc.

Domestic freshwater system of a tanker vessel

- Deck services

Water from the drinking water hydrophore tank supplies

through the mineralising filter to:

- Accommodation drinking water

- Water fountain in engine room

In figure above for instance shown domestic freshwater system of a tanker vessel.