Air purification

Purifying the air from the material trapped in it by filtration is the first step of the air conditioning process. Air filtration can be done using different machines and systems designed and methods in accordance with the purpose. Since the air inside the engine room, generator room and battery rooms is already hot, humid and contains oil, fuel, acid vapor, air filtration is not required. These places are supplied with 100% fresh air. On the other hand, filtration is necessary where the air circulate continuously according to certain standards in cases where air quality, temperature and humidity are vital and energy saving is at the forefront.

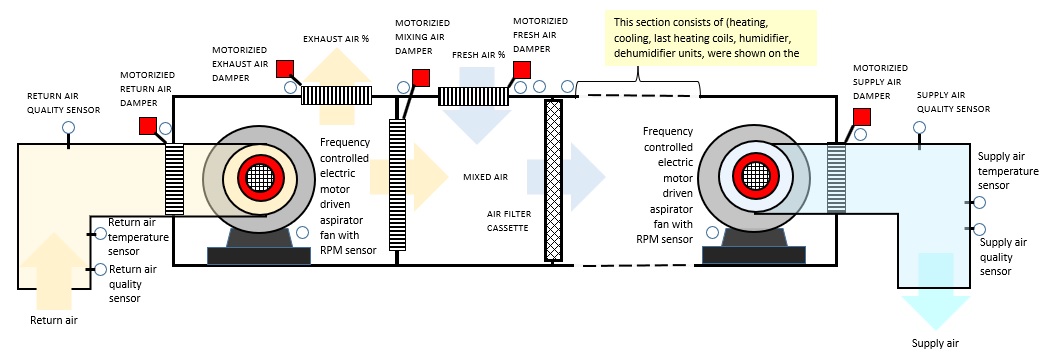

Operation of the systems required for air filtration of specific spaces, such as customer and personnel living quarters, warehouses, kitchens and toilets or the holds for animal, vegetables, fruits, are under the responsibility of Marine Engineers. There are several places on merchant ships that constantly need filtered air. Many types of filters are used for filtration. For this purpose, a wide variety of filters are used in ventilation and air conditioning devices. The next picture shows the layout of a typical filter inside the AHU, whose permeability is controlled by a differential pressure switch with air participation before and after the filter.

Hospitals, shopping malls, various living spaces, hotels, etc. absolutely need air filtration to remove the suspended physical substances as well as bacteria circulating in the air. Cassette type filters (Figure. 15) installed in air handling units (AHU), is the most common application used for air purification. Marine Engineers are responsible to maintain air filtration properly in spaces of the ships, where air circulation due to energy saving as well as air quality is a major factor in terms of air conditioning.

Air purification can be done at ships by means of different devices and methods in accordance with the purpose. Since the air, in engine, generator and battery rooms, is always hot, humid and contaminated with suspended material such as dust, oil, fuel and acid mists, generally air purification is not required. Permeability of air filters is one of the most important factors affecting air condition efficiency, quality and energy savings.

The permeability of a filter is measured by the pressure difference between the surfaces where the air enters and exits the filter. In dirty filters, the pressure difference between the front and back of the filter is large. High inlet air pressure but low outlet pressure is the best indication that the filter is dirty. In such a case, an alarm appears on the control panel, warning that the filter is dirty. Marine Engineer does the necessary work for changing the filter and cleaning the dirty one.

Cleaning of air filters is essential for cargo and life quality. When cleaning is delayed, particles passing through the filter over time cause the heating and cooling coils to become clogged. Such a situation necessitates a more detailed, troublesome and long mechanical cleaning. On the other hand, the efficiency and air quality of the AHU with clogged filters and coils decreases, while the energy consumption of the air handling unit, which tries to fulfill the desired conditions, increases.

Figure.15 Aspirator, air filter and ventilator units of air handling unit