Central air-conditioning system

Warehouses, machine rooms and working areas, where large amounts of heat transfer are needed, are air-conditioned with a central system. For cooling these spaces either direct refrigerant gas, or with cool-water produced with refrigerant gas compressor or, absorbtion unit, is used (Figure.13). The hot water or steam, required for heating in central system, is obtained from the heat recovery boiler (Figure.14).

Source of heat transfer for cooling

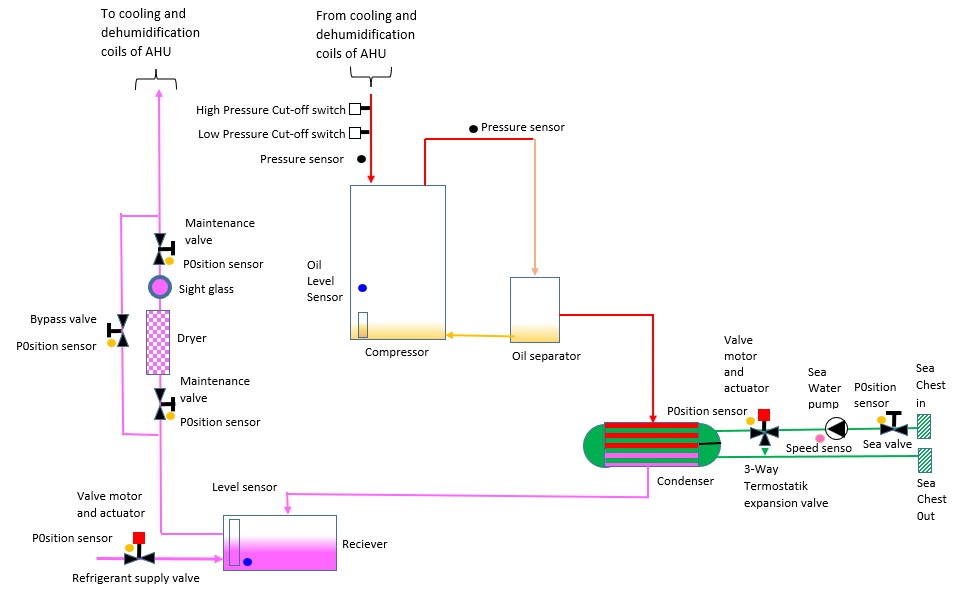

One of the tasks of the air conditioning system is to adjust the temperature of the place it supplies by applying the most appropriate ventilation method. In order to reduce the ambient temperature to the set value, the water temperature is reduced to 5-12 °C by cooling system. Until the temperature of the air achieve to the set value the chilled water continues to pass through the cooling coil in the air handling unit. Marine Engineer is responsible to ensure the efficient and effective operation of all system elements that take place in producing chilled water between 5-7 °C and circulating in the cooling coils. He/she must set the correct operating values, make necessary adjustments, calibrate all sensors, monitor, analyze and define the operating values, make decision for correction and apply whenever necessary. A typical air-conditioning system, consists of main components and the connections made to the air handling units (AHU) for revitalization of the circulated air, is represented with the image below.

Figure.13 Cool water production system with refrigerant gas compressor

Source of heat transfer for heating

Heat recovery hot water, steam or thermal oil heating systems are commonly applied for heating the ships heavy fuel oil and/or liquid cargo. These systems also providing the heat for HVAC, hot water, etc. on a ship. The thermal oil heating systems are known for their long life, low maintenance and high efficiency.

The water temperature, heated up to 50-70 °C in these boilers, is then pumped to the heating coils in the AHU by means of pumps. The steam obtained in the steam boilers, is first sent to the heat exchangers to heat the heating water temperature up to 70-90 °C to be used at AHU units. For fan-coil units for heating or cooling small volumes heating water temperature is adjusted to 50-70 °C by thermostatic expansion valves. In order to save fuel and heat in air conditioning processes in modern air-conditioning applications, absorbent systems fed by recovery of exhaust gas is used for heating the water. Solar energy can also be used in air-conditioning system designs if suitable installations are provided.

Figure.14 Hot-water/steam production by scotch/heat recovery boilers